Sensing devices in industrial applications often operate in harsh environments. To ensure their long-term reliability, effective protection against dust, water, chemicals or temperature extremes is important. Argutec's special covers provide a reliable barrier against external influences that could lead to irreversible damage to sensitive electronics.

The industrial camera, including the necessary lens, is the most common sensing device. However, it lacks protection against mechanical damage, dust, and possibly water or chemically aggressive environments. Cameras and lenses are also not 100% able to withstand thermal shocks and are not designed to be safely mounted to robust structures.

To help you avoid these risks and ensure trouble-free operation of your camera system, we have long focused on manufacturing suitable industrial enclosures. These are specifically designed for harsh conditions. Investing in an industrial camera housing is essential to ensure its long-term functionality and reliability. A properly selected cover will protect the camera from external influences, ensure safe installation on structures and uninterrupted operation of technological processes.

Temperature

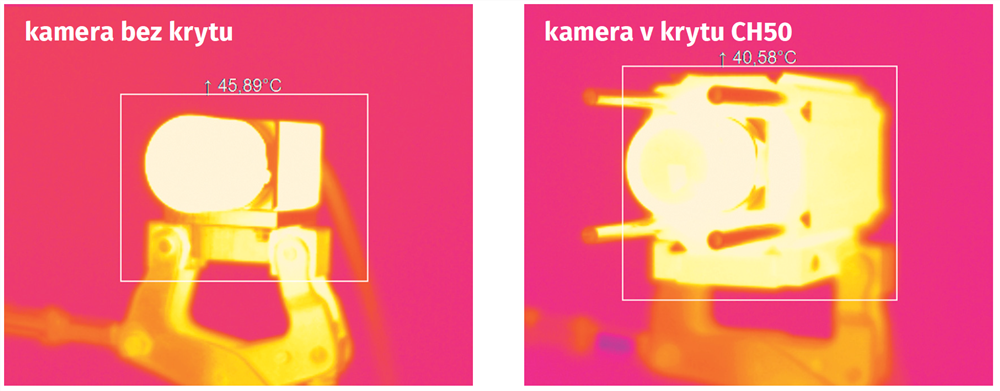

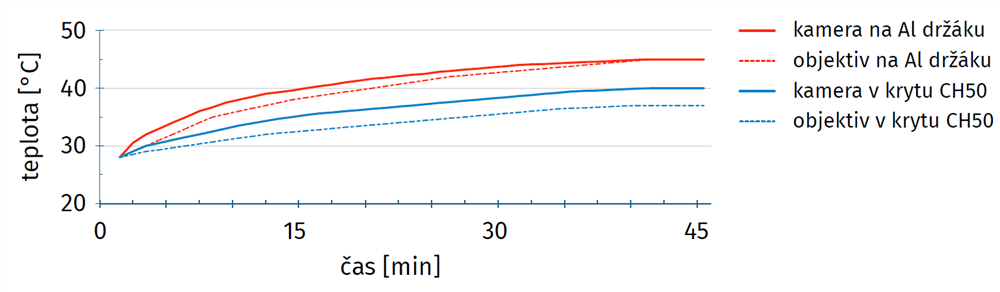

High or low temperatures in industrial environments can adversely affect the function of the sensing device. Thanks to the sophisticated mounting of the camera, with excellent thermal conductivity, passive cooling is ensured in case of higher operating temperatures. The temperature of the camera is significantly reduced only by passive cooling of the CH50 housing.

It can be seen from the temperature history that the CH50 housing maintains a lower camera temperature. The effect on the lens is significant—without the enclosure, nearly all the camera's heat is transferred to the lens. However, with the cover dissipating heat, the lens stays cooler as shown on the thermal camera photos bellow.

Mechanical damage

The enclosure protects the fragile camera and lens from impact and other mechanical influences that could damage the internal components. In terms of wiring, the cover is equipped with a cable gland to allow for quality connection and protection of the connectors.

Chemical protection

For chemically aggressive environments, an enclosure made of resistant material such as stainless steel or special plastics is suitable. These protect the camera, visor and cabling from corrosion and damage from aggressive chemicals.

Dust and water

Dust that enters the camera or lens can cause irreversible damage. High IP rating housing provides reliable protection against the ingress of water and dust. An additional air blower on the front further keeps the vi of the enclosure clear at all times by simply blowing away settled dust and water, allowing for flawless images.

IP (Ingress Protection) ratings

For industrial cameras, protection ratings that ensure dust and water resistance are key. The most commonly used are IP68 and IP69.

Choosing the right IP rating is key to ensuring the industrial camera's reliable and long-lasting functionality in the environment. It is necessary to consider the specific operating conditions and select an enclosure with the appropriate level of protection.

Below we present an excerpt from the table that explains the degrees of coverage:

| First digit | IP6X | Full protection against dust ingress. |

| Second digit | IPX6 | Protected against intense water spray. Water is directed at all angles at a flow rate of 100 litres per minute at a pressure of 100 kN/m² for at least 3 minutes from a distance of 3 metres. |

| IPX8 | Full protection against water ingress in case the cover is submerged under water. Immersion resistance is determined by the manufacturer's parameters. | |

| IPX9 | Full protection against water ingress due to high pressure and high temperature. |

IP69 (IP69K)

Our CH50 enclosure has been certified from the start to IP66, specifically for industrial environments where pressurized water is present. Due to the proliferation of requests for installation in food processing plants, the CH50 enclosure has now been IP69 certified without any design changes. The test for IP69 certification according to EN 60529 is the same as the test for IP69K certification according to ISO 20653.

IP68

The new CHS50 enclosure is made to meet the requirements of IP68, which makes it suitable for all under underwater applications. It´s designed to withstand the pressure of upto 5 bars. The stainless steel design also makes it perfect for protection against chemicals, making it the perfect choice for the chemical industry. A version meeting the specific hygienic requirements of the food industry is comming soon.

Extending lifetime and reducing costs

Investing in a quality enclosure pays off in the long run. Protecting your camera extends its life and reduces repair and replacement costs. Setting up the lens or handling the camera directly is easier in a housing that is split and equipped with guide rods. Removing and then reassembling the front of the housing can be done with one hand, reducing the time needed to maintain the camera and lens.

Other advantages of industrial camera covers

In addition to protection from the elements, the covers offer other benefits:

- Flexibility: there is a wide range of enclosures in different sizes and designs that can be adapted to the specific needs of the application. Covers are available for different types of cameras, lenses and mounting systems. See the section of Atypical products to learn more.

- Aesthetics: enclosures can also improve the aesthetic appearance of the installation and hide (protect) cables and connectors. Further more, you can use the body of the housing to showcase your brand by having your own logo printed on it. This service is provided for orders of 20+ pieces.

An industrial camera cover is not just an accessory, but an essential part of any camera system in a harsh industrial environment. It provides reliable protection from damage, extends the life of the camera and reduces maintenance and repair costs. Thus, investing in a quality housing will clearly pay off in the long run. When selecting an enclosure, it is important to take into account the specific environmental conditions and requirements of the application and to consult personally with enclosure suppliers.